In the world of manufacturing, finding materials that are strong, lightweight, and versatile is essential. One material that has gained popularity across many industries is aluminum. Aluminum extrusions, in particular, have become a key solution for manufacturers looking to improve efficiency, reduce costs, and create high-quality products. By understanding how aluminum extrusions work and the benefits they offer, companies can transform their manufacturing projects and achieve better results.

What Are Aluminum Extrusions?

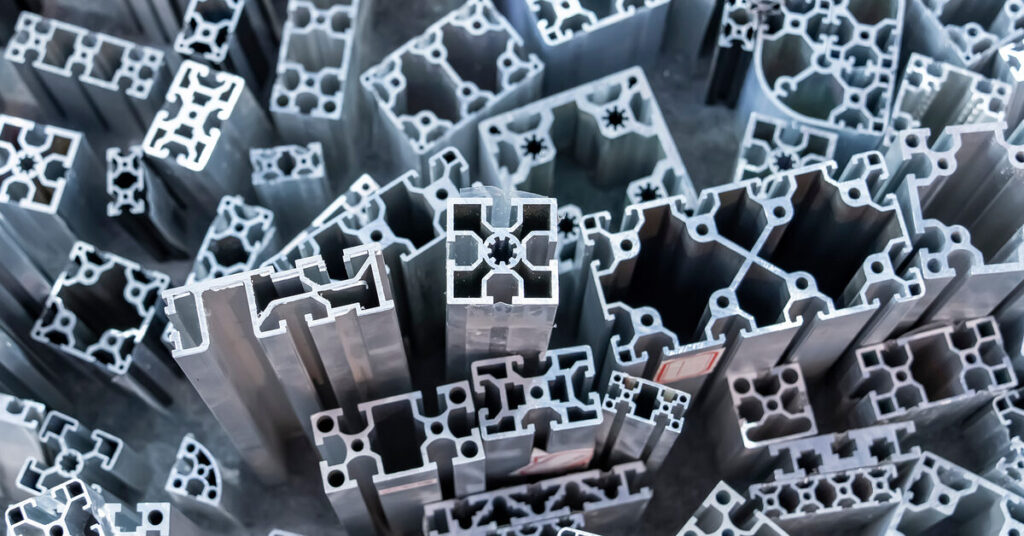

Aluminum extrusions are products created by shaping aluminum metal through a process called extrusion. In this process, aluminum is heated and pushed through a specially designed die, which forms the metal into a specific shape. The result can be a simple rod, tube, or a complex profile designed to fit precise requirements. This process allows manufacturers to create custom shapes that meet specific project needs without wasting materials. The flexibility of aluminum extrusions makes them suitable for a wide range of industries, from construction and transportation to electronics and machinery.

Strength and Durability of Aluminum Extrusions

One of the main advantages of aluminum extrusions is their strength. Despite being lightweight, aluminum can withstand heavy loads and harsh conditions. This makes it ideal for manufacturing projects that require durable materials but cannot afford to add unnecessary weight. Aluminum extrusions are also resistant to corrosion, meaning they maintain their strength and appearance even when exposed to moisture or chemicals. For manufacturers, this translates into products that last longer and require less maintenance, ultimately saving time and money.

Lightweight and Cost-Effective Solution

Aluminum is naturally lighter than many other metals, such as steel. Using aluminum extrusions in manufacturing projects reduces the overall weight of the product, which can improve performance and efficiency. For example, in transportation industries, lighter materials can lead to better fuel efficiency and easier handling. In addition, the extrusion process itself is highly efficient, producing minimal waste. This makes aluminum extrusions a cost-effective choice for companies looking to maximize resources without compromising quality.

Design Flexibility with Aluminum Extrusions

One of the most exciting aspects of aluminum extrusions is the design flexibility they offer. Manufacturers can create complex and precise shapes that would be difficult or impossible with other materials. Aluminum extrusions can be customized in size, length, and cross-sectional profile to meet the exact requirements of a project. This flexibility allows engineers and designers to innovate and produce products that are both functional and aesthetically appealing. Additionally, aluminum extrusions can be easily machined, drilled, or joined with other components, making assembly faster and more efficient.

Sustainability and Environmental Benefits

In today’s manufacturing world, sustainability is a major concern. Aluminum is a highly recyclable material, and using aluminum extrusions can significantly reduce environmental impact. Recycled aluminum requires less energy to produce than new aluminum, which helps companies lower their carbon footprint. Choosing aluminum extrusions is not only good for the environment but also aligns with modern manufacturing practices that prioritize eco-friendly solutions. This makes aluminum extrusions an attractive option for companies committed to sustainable growth.

Applications Across Industries

Aluminum extrusions are versatile and can be used in a wide variety of industries. In construction, they are used for window frames, curtain walls, and structural components. In transportation, aluminum extrusions are found in automotive frames, aircraft parts, and railway components. Electronics manufacturers use them for heat sinks, enclosures, and structural supports. Even the furniture industry benefits from aluminum extrusions due to their lightweight and durable properties. The wide range of applications shows that aluminum extrusions can adapt to almost any project, enhancing efficiency and product quality.

Conclusion

Aluminum extrusions offer a combination of strength, durability, lightweight design, and flexibility that can transform manufacturing projects. By using aluminum extrusions, companies can reduce costs, increase efficiency, and create innovative products that meet modern demands. Their sustainability and wide range of applications make them an ideal choice for industries looking to improve performance while minimizing environmental impact. Adopting aluminum extrusions in manufacturing projects is not just a practical decision; it is a strategic step toward achieving long-term success and innovation in today’s competitive market.